INDUSTRIAL AUTOMATION WHAT IS INDUSTRIAL AUTOMATION?

|

INDUSTRIAL AUTOMATION WHAT IS |

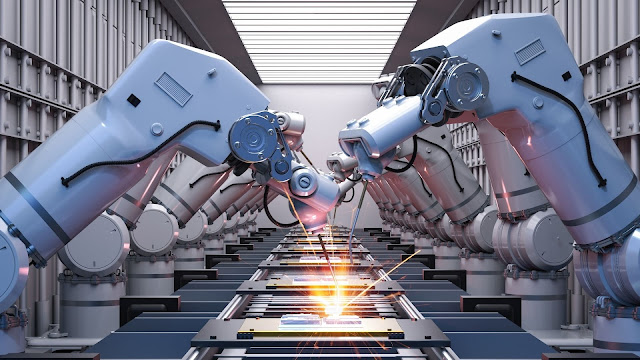

Industrial automation can be defined specifically as the use of mechanical or electronic industrial systems to generate dynamic and controlled behavior, through commands and rules that manage to maintain the production operation in a certain service, and that implies the reduction of work. human resources and simplification of work processes.

Automation of industrial processes

Historical background

For many centuries, human beings have sought a remarkable and precise way to achieve work with a significant reduction in physical effort, when using various types of tools and machinery.

In the first stage, the machines created reduced the enormous human effort, simplifying the work by being handled by themselves through some techniques as simple as pulleys and levers.

With the arrival of the Industrial Revolution, work paradigms were broken that led to displacing the use of human and animal energy, due to the incorporation of other resources that helped automation, such as the wind, the sea, and the flow of water.

During the 19th and 20th centuries, the first automated systems appeared that incorporated mechanical systems that used channeled flows of water and steam to generate repetitive actions in the production of various objects, such as mechanical looms and steam machines.

The deepest automation has been carried out since the 1960s, with the arrival of computers that led to the creation of equipment that is required and to achieve control of electronic processes, with an emphasis on automation engineering, already allowing in our century more efficient use of robots and devices that guarantee industrial automation with the incorporation of aspects such as the programmable logic controller (PLC).

OBJECTIVES OF THE AUTOMATION OF INDUSTRIAL SYSTEMS

Industrial automation seeks to consolidate and achieve various objectives by incorporating processes through automation engineering, process pyramid, technologies, techniques, and instruments. Among the main objectives of industrial automation are:

- Rationalize the various production processes and generation of inputs.

- Carry out corrective actions and improvements in work processes within the human environment.

- Minimize failures and reduction in execution time of various tasks.

- Reduce costs in processes through the use of robots, mechanical devices, controllers, and sensors. Generating a fast return on investment.

- Avoid possible significant occurrences of human errors and reduce labor problems due to stress.

- Increase traceability in aspects related to the creation, management, and distribution of activities in the production lines, standardizing processes.

WHERE IS AUTOMATION APPLIED IN INDUSTRIAL PROCESSES?

Industrial automation can be applied in various areas such as basic industries, production industries, goods, and services industry, services and automation and agricultural, automotive industrial processes, among many others.

Industrial automation can also include services in some financial entities, the oil industry, power generation companies, communications companies, telematics product companies, medical supply industries, to mention the most relevant and high-impact ones.

Components and equipment that are implemented

Generally, among the main aspects that are incorporated into the activities of automation, control of electronic processes, control of machines, systems, and industrial processes, a series of fundamental equipment is required, such as sensors, pre-actuators, actuators, controllers, machine interfaces (HMI), programmable logic controller (PLC) panels, power, and command circuits, to mention those related to the process pyramid and the automation pyramid.

Advantages and disadvantages

Automation has many advantages depending on considering the notable aspects of help and improvement through technologies, techniques, and instruments that are incorporated into industrial processes:

- Significantly increases the production of any service or product

- Productivity is improved at accelerated levels

- Provenly reduces production costs by basing much of the activities on automation engineering

- Electronic process control can be maintained

- Improve job security

- The quality of the various products is increased

- Reduce production times

- It favors the incorporation and generation of automated factories

When referring to the most obvious possible disadvantages of automation, we can consider the following aspects:

Investment costs in system installation processes can be considered high.

- In some aspects, there may be too much technological dependency according to the choice of suppliers.

- Technological obsolescence can manifest quickly depending on the time between amortization and return on investment that has occurred.

- In some areas it is more difficult to find professionals specializing in industrial automation processes, and if they are found they will be more expensive to hire.

- In the event of starting automation processes with erratic operations, the succession of errors that manage to include a deterioration in service quality and execution times in processes can become very evident.

- It has always been considered that the instruction of industrial automation processes is perceived to create environments of uncertainty due to possible job losses.

- industrial automation

TYPES OF INDUSTRIAL AUTOMATION

Currently, there are various types of automation in all activities that require the use of a process pyramid associated with industrial automation, they are mainly related at management levels, planning levels, supervision levels, control level, and field-level...

Fixed

Fixed automation corresponds to that used to standardize various operations repetitively and fixedly, to achieve high levels of production, they are closely related to assembly operations with fixed sequences such as the automotive industry since it mainly requires that the product not be changed.

Flexible

It is a type of automation that implies that automatic control operations may have variability in their flexibility to execute possible changes in the production or design of the products.

It is very useful in the case of automation systems for guided vehicles or machines with numerical control.

Programmable

It is a process that is closely related to important changes that can be made at the processing and assembly level through changes in the control orders of the automated equipment.

It is widely used to reconfigure or adapt in processes that involve volume and batch production.

Hybrid

Hybrid automation is related to the incorporation of the assignment of tasks according to requirements or needs. Generally, under a back-office format. It is widely used in various business processes such as a call center and purchase orders.

In many cases, a robot directly executes a programmed action and can guide a certain user to fulfill its requirements. It is very useful to complete processes that could be very long or tedious.

types of industrial automation

IMPORTANCE OF ROBOTICS IN INDUSTRIAL AUTOMATION

The incorporation of robotics has been a fundamental element for the growth of industrial automation and its projection as part of creating a high level of productivity and generating greater applications of high repetitiveness that has led to a reduction in human errors. It has led to improving the quality levels of many products for substantial money savings and faster return on investment.

EXAMPLE OF INDUSTRIAL AUTOMATION

There are several examples related to industrial automation, a very obvious one is what happens in the automobile industry, where various robots are in charge of the production and integration cycles of the various parts of a car. Therefore, great performance is generated in aspects ranging from the manufacture of the chassis to the automobile engines, using various Modular PLCs, HMI interfaces, servo amplifiers, numerical controls, and software that have allowed many companies to achieve greater profit return. by reducing operating costs.

conclusion

In conclusion, industrial automation with the arrival of new technologies has allowed its incorporation in large, medium, and small industries, making industrial processes efficient, competitive, and very safe.

Industrial automation has generated the ability to have many necessary resources through computerized elements to be able to effectively control and improve many tasks with a reduction in errors, causing an increase in production efficiency with a reduction in direct costs for supplies and stock expenses...

No comments:

Post a Comment